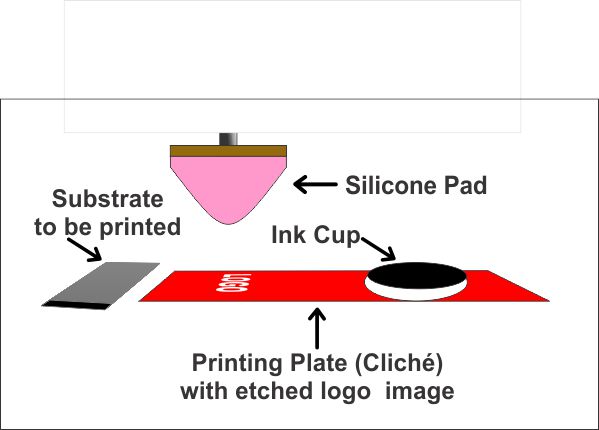

What is Pad Printing / How it Works

Pad Printing Explained

Pad printing is a indirect gravure printing process that transfers an image onto irregular shaped, recessed or three-dimensional products utilizing a silicone pad. The unique properties of the silicone pad enable it to pick the image up from a photographically created printing plate and transfer the image to a variety of surfaces, such as flat, round, textured, uneven, concave, or convex surfaces. Our pad printer is used for printing on products that would be difficult or impossible to print using our screen print method. Products we print using the pad printing process include, but are no limited to: promotional items, medical and automotive parts, electronic devices, coffee mugs, CDs and DVDs, and toys. |

|

Using a photographic process, the image to be printed is etched onto a Polymer coated steel plate. A silicone pad is selected depending on the size and shape of the object to be printed. The proper ink is selected and mixed to match the material to be printed, then the "Ink Cup" is filled.. |

|

|

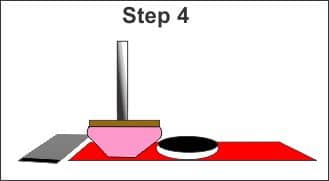

The ink cup moves across the etched logo on the printing plate leaving a thin coating of ink in the logo recess. | |

|

The cup retreats and the top surface of the ink is exposed to air. During this crucial fraction of a second, solvent evaporates from the ink leaving the exposed top service tacky. | |

|

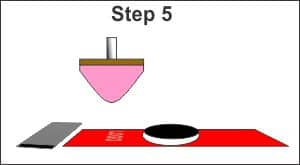

The silicone pad lowers and presses against the now sticky ink. | |

|

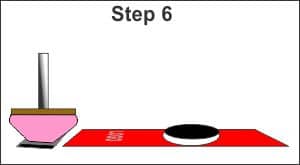

The pad now rises with the ink adhered to it. Now begins the next crucial fraction of a second. The bottom surface of the ink is exposed to air, solvent evaporates from the ink leaving the exposed bottom service tacky. | |

|

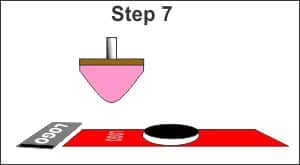

The pad moves to the substrate to be printed, and presses down. | |

|

The pad rises leaving behind a perfect duplication of the original image. All of these steps take place in only Four Seconds. |

|

Learn More About Pad Printing Here

Contract Pad Printing Service

Call us today for a quote

on your Pad Printing Project

Contact Us